How to maintain AGV wheels

Automated Guided Vehicles (AGVs) are material handling systems that operate on wheels or casters. The wheels play a critical role in ensuring the smooth movement of AGVs, and therefore, they need to be well-maintained to prolong the lifespan of the AGV. Here are some tips on how to maintain AGV wheels

Inspect the wheels regularly: Regular inspections help to identify any signs of wear and tear on the wheels. Inspect the wheels for any damage, such as cracks, flat spots, or worn-out treads. Any deformities can cause instability and affect the accuracy of the AGV's movement.

Keep the wheels clean: Dirt, debris, and other contaminants can accumulate on the wheels over time, causing wear and tear. Regular cleaning of the wheels using appropriate cleaning agents and methods, such as vacuuming or pressure washing, can help prevent dirt and debris from accumulating and causing damage.

Lubricate the wheels: Lubrication of the wheels reduces friction, preventing the wheels from wearing out prematurely. Regular application of lubricants such as oil or grease can help to reduce wear and tear on the wheels, prolonging their lifespan.

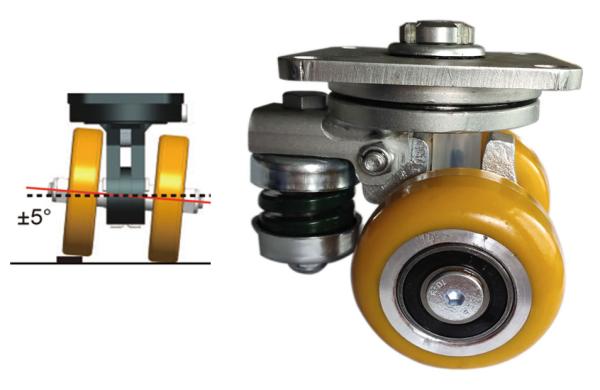

Check the alignment: Wheel alignment is crucial for the proper operation of the AGV. Misaligned wheels can cause the AGV to move off course, affecting its performance. Regular alignment checks can help to ensure that the AGV's wheels are aligned correctly.

Check the pressure: The wheels' pressure must be maintained at the recommended level to ensure proper operation. Too little pressure can cause the tires to wear out more quickly, while too much pressure can cause the AGV to bounce and lose stability.

Replace worn-out wheels: When the wheels are worn out, they need to be replaced promptly. Replacing the wheels on time can help to prevent more damage to the AGV and prolong its lifespan.

Train operators: AGV operators should be trained to handle the equipment properly, including the wheels. They should be aware of the importance of regular maintenance and should report any signs of damage or wear to the maintenance team promptly.

In summary, regular inspection, cleaning, lubrication, alignment, and pressure checks can help to maintain AGV wheels. Additionally, replacing worn-out wheels promptly and training operators to handle the equipment properly can help to prolong the AGV's lifespan and ensure its proper functioning.

English

English Spanish

Spanish German

German Russian

Russian Arabic

Arabic Portuguese

Portuguese Italian

Italian French

French Hebrew

Hebrew Turkish

Turkish