The future of AGV casters

04 Sep / 2023The future of AGV (Automated Guided Vehicle) casters holds great potential as advancements in technology continue to shape the industry. AGVs are autonomous vehicles that navigate and transport goods within various industries, including logistics, manufacturing, healthcare, and more. AGV casters play a crucial role in the movement and maneuverability of these vehicles. In this article, we will explore the future trends and developments that could shape the future of AGV casters.

Enhanced Navigation Capabilities: One of the key areas of development for AGV technology is improved navigation capabilities. As AGVs become more sophisticated, they will require casters that can handle intricate navigation tasks. This may involve the integration of advanced sensors, such as LiDAR (Light Detection and Ranging), cameras, or computer vision systems into the casters themselves. These sensors will enable AGV casters to detect obstacles, map their surroundings, and make real-time decisions to optimize their path planning.

Artificial Intelligence (AI) Integration: AI plays a significant role in enhancing the capabilities of AGVs. In the future, AGV casters may incorporate AI algorithms to analyze data collected from sensors and make intelligent decisions. AI integration can enable AGV casters to adapt to changing environments, optimize routes, and even learn from experience to improve overall performance and efficiency.

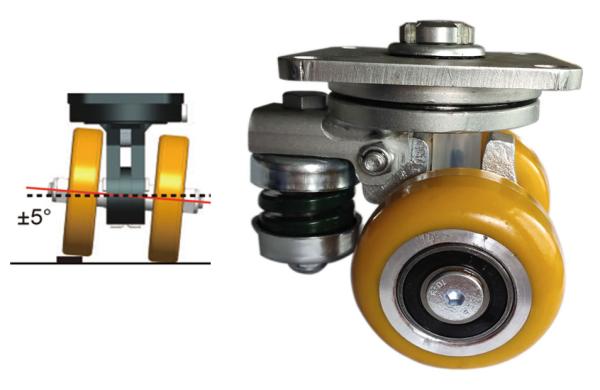

Multi-Terrain Adaptability: AGVs are increasingly being used in various industries and environments, ranging from warehouses to outdoor spaces. Future AGV casters will need to be adaptable to different terrains, including uneven surfaces, ramps, or even stairs. Casters with adjustable height, shock absorption capabilities, or specialized treads designed for specific terrains will become more prevalent.

Increased Load Capacity: AGVs are used to transport goods of varying weights and sizes. To accommodate heavy loads, AGV casters will need to have increased load capacities. Future AGV casters may utilize advanced materials, such as carbon fiber composites or high-strength alloys, to improve their load-bearing capabilities without compromising maneuverability.

Energy Efficiency: As sustainability becomes a crucial consideration, AGV casters will likely become more energy-efficient. Future advancements may include the integration of regenerative braking systems, where the energy generated during deceleration or braking is stored and reused. This will help to extend the battery life of AGVs and reduce overall energy consumption.

Connectivity and Communication: The future of AGV technology lies in its ability to connect and communicate with other devices and systems. AGV casters may feature built-in communication modules, enabling seamless integration with warehouse management systems, inventory control systems, or other AGVs. This connectivity will allow for coordinated movement, real-time data exchange, and improved overall workflow efficiency.

Maintenance and Self-diagnosis: Future AGV casters may incorporate self-diagnostic capabilities to monitor their performance and identify potential issues. These casters could generate alerts or notifications when maintenance or replacement is required, improving uptime and reducing the risk of unexpected failures. This proactive approach to maintenance will contribute to the overall reliability and performance of AGV systems.

Enhanced Safety Features: Safety is paramount in any industrial setting. Future AGV casters may integrate advanced safety features to prevent collisions, provide obstacle detection, or include emergency stop mechanisms. These safety features will not only protect goods but also ensure the safety of workers sharing the same workspace with AGVs.

Modular Design: AGV casters may adopt a modular design approach, allowing for easier customization and replacement of components. This modularity can simplify maintenance and repairs, reduce downtime, and enable quick upgrades or modifications to meet changing operational needs.

Continuous Research and Development: The future of AGV casters relies heavily on ongoing research and development efforts. Manufacturers, researchers, and industry experts will continue to collaborate to advance AGV caster technology. This includes exploring new materials, testing innovative designs, and refining existing features to optimize performance, durability, and functionality.

In conclusion, the future of AGV casters holds great promise as technology continues to evolve. Enhanced navigation capabilities, integration of AI, multi-terrain adaptability, increased load capacity, energy efficiency, connectivity and communication, maintenance and self-diagnosis, enhanced safety features, modular design, and continuous research and development are some of the key areas that will shape the evolution of AGV casters. These advancements will contribute to more efficient and reliable AGV systems, paving the way for increased automation and optimization in various industries.