- Best Price! Direct China Factory!

- Send Inquiry

WhatsApp/WeChat: 0086-137-36454395

Assessing the quality of Stryker stretcher wheels involves a comprehensive evaluation of several key aspects. Stryker is a well-known manufacturer of medical equipment, including stretchers and their components, and their products are expected to meet high standards of durability, reliability, and performance in clinical environments. In this detailed guide, we'll explore the various factors that contribute to judging the quality of Stryker stretcher wheels.

1. Material and Build Quality

The foundation of any good stretcher wheel lies in its materials and construction. Quality wheels are typically made from durable materials such as high-grade plastics, rubber, or composite materials. These materials are chosen for their ability to withstand repeated use and various environmental conditions encountered in healthcare settings.

* Plastics: High-quality plastics like reinforced polypropylene are commonly used for stretcher wheels due to their lightweight nature and strength. They offer good resistance to impact and wear.

* TPE: TPE wheels are known for their shock-absorbing properties, which can contribute to smoother movement and reduced noise levels. They also provide good traction on different floor surfaces.And will not leave mark on the floor.

* Composites: Some wheels use composite materials that combine the best properties of plastics and rubbers, offering a balance of strength, durability, and noise reduction.

The build quality includes the design and manufacturing precision. Well-engineered stretcher wheels will have smooth surfaces, tight tolerances to minimize wobbling, and robust construction to handle the weight and stresses they encounter during use.

2. Smoothness of Movement

One of the primary functions of stretcher wheels is to facilitate smooth and easy movement of the stretcher, both when pushing and maneuvering corners. Factors that contribute to smooth movement include:

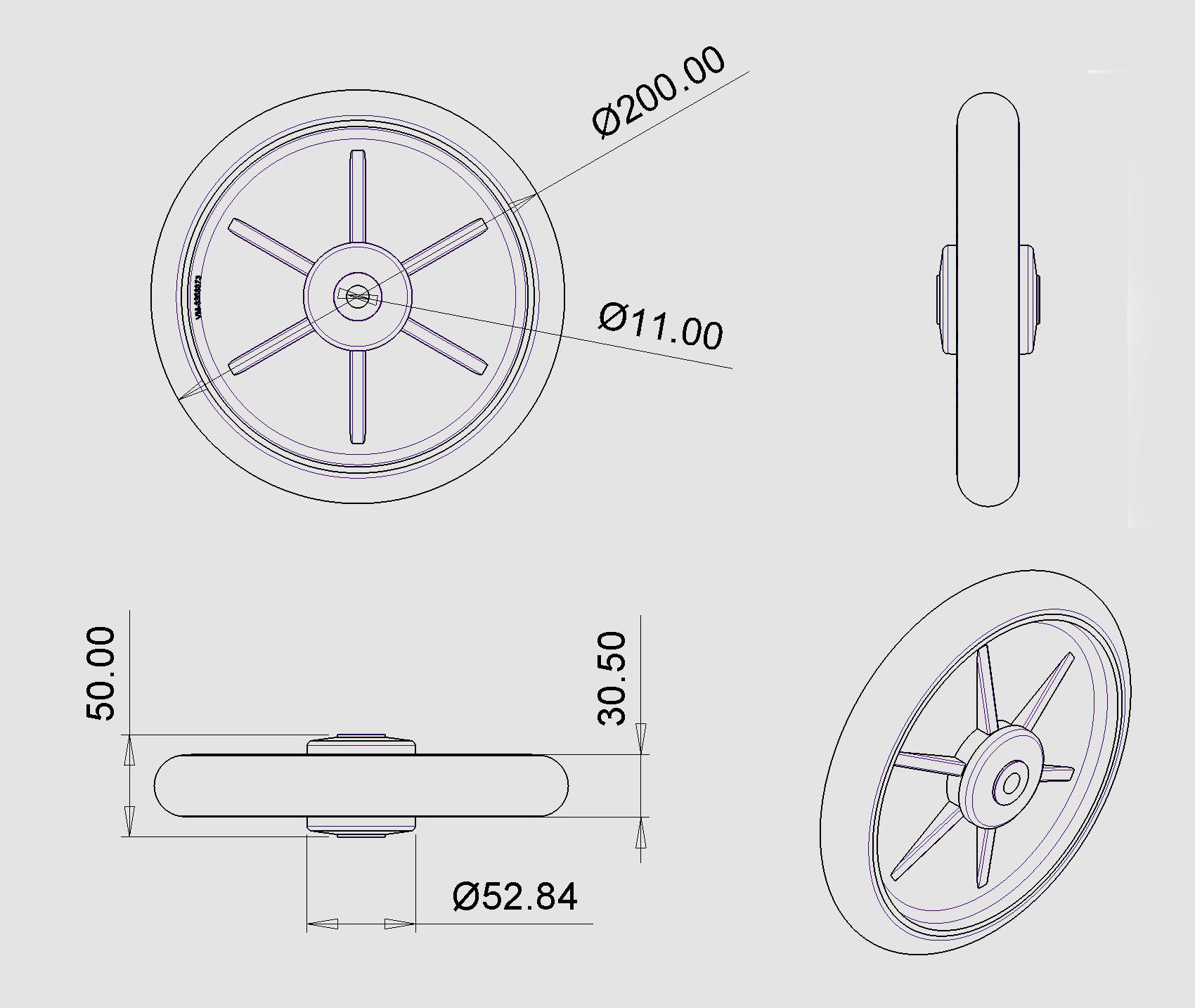

* Wheel Design: The design of the wheel itself impacts its ability to roll smoothly. Large diameter wheels generally roll more easily over obstacles and imperfections in the floor.

* Axle Quality: The axle should be sturdy and well-lubricated to ensure smooth rotation of the wheel without friction.

* Wheel Bearings: Quality bearings inside the wheel hub reduce friction and enable smoother rolling. Bearings should be sealed to prevent contamination from dirt and fluids.

During evaluation, testing the stretcher's movement across different floor surfaces (e.g., tile, carpet) can reveal how well the wheels perform under typical hospital conditions.

3. Weight Capacity

* Stretcher wheels must support the weight of patients and medical equipment without compromising stability or performance. Factors related to weight capacity include:

* Load Rating: Manufacturers specify weight limits for their stretcher wheels. Higher load ratings indicate stronger materials and construction, capable of supporting heavier loads.

* Distribution of Weight: The design of the stretcher frame and wheel placement affect weight distribution. Even weight distribution across all wheels ensures balanced and stable movement.

* Impact Resistance: Wheels should be able to withstand sudden impacts or uneven weight distribution without deforming or failing.

4. Noise Levels

* In healthcare settings, noise can affect patient comfort and staff productivity. Quality stretcher wheels operate quietly, contributing to a calm environment. Factors influencing noise levels include:

* Wheel Material: TPE wheels dampen vibrations and reduce noise compared to hard plastic wheels.

* Bearing Quality: Smooth-running bearings reduce frictional noise. Sealed bearings also prevent dirt ingress, maintaining quieter operation over time.

* Maintenance: Regular lubrication and upkeep of wheels and bearings can prevent squeaks and ensure quiet operation throughout the wheel's lifespan.

5. Ease of Maintenance

* Maintenance requirements can affect the long-term performance and lifespan of stretcher wheels. Factors influencing ease of maintenance include:

* Accessibility: Easily accessible parts facilitate quick inspections and maintenance tasks.

* Cleaning: Smooth surfaces and materials that resist corrosion and are easy to clean contribute to hygiene and longevity.

* Replacement Parts: Availability of spare parts and ease of replacement can reduce downtime and extend the life of the stretcher wheels.

Assessing the quality of Stryker stretcher wheels involves a holistic evaluation encompassing material quality, smoothness of movement, weight capacity, noise levels, ease of maintenance, manufacturer reputation, and adherence to standards. By carefully examining these factors, healthcare facilities can make informed decisions that ensure patient comfort, safety, and operational efficiency.

Ø200mm x 30.5mm wide , Precision double ball bearings + Low noise TPE Tread

Anti-winding caps, Tread color both Grey and black are available

English

English Spanish

Spanish German

German Russian

Russian Arabic

Arabic Portuguese

Portuguese Italian

Italian French

French Hebrew

Hebrew Turkish

Turkish