Why Do AGVs Have Special AGV Casters?

AGVs are a highly important part of most industries. They are used in a large number of facilities for the transportation of equipment and materials from one place to another. AGVs are crucial for the production and manufacturing processes in most industries.

An AGV or Automated Guided Vehicle is an Automated vehicle usually maneuvered through the help of a controller that you can use from a remote location. Because it does not have a driver of its own, it may be easy to use, but it is difficult to gauge the pressure exerted on the casters of the AGV and the extent of the load it is carrying from a distance. However, they are very convenient in most facilities mainly because they do not have a driver on board.

We are here to discuss the casters used in all AGVs and the main purpose they serve. We want to know if it is truly necessary for AGVs to have specialized casters, or are mass-produced, general casters good enough for all AGVs? Let’s find out more about the kind of casters you can make use of in an Automated Guided Vehicle.

First, however, it is important for us to know exactly what an AGV should seek in a caster.

The AGV Caster Needs Of An AGV

Broadly speaking, the main differentiating factor of an AGV from other transporting vehicles and carts is that AGVs do not have a driver on board. They are moved from a remote location with the help of a controller. Naturally, it is difficult for an individual to gauge from afar when an AGV is overloaded, where there is too much pressure on the caster or when the casters are about to give in.

Because of this reason, it is important to choose casters that will not give in easily and can handle heavy loads so as to prevent any mid-transportation failure.

Other than that, the type of caster you end up choosing for your AGV will also depend on the industry that you are working in. For example, if the work requires transportation of heavy loads, you should use heavy-duty or shock-absorbing AGV casters. Suspension AGV casters or low-profile casters are also highly useful in these situations. On the other hand, leveling AGV casters can be deployed for AGVs that need to be adjusted on a different level to allow the load to be shifted from one place to another.

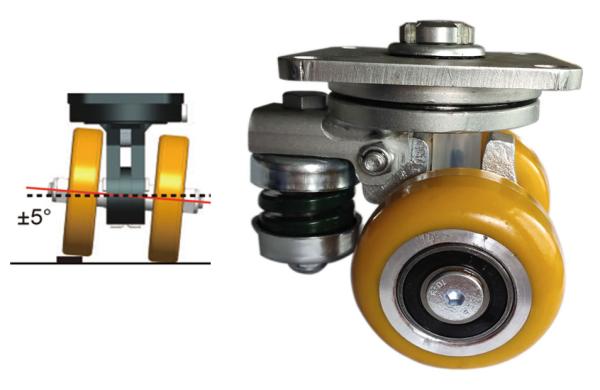

If the AGV needs smoother and more efficient movement and the loads are not too heavy, you can make use of swiveling casters or twin casters. These casters allow for some shock-absorption and can bear heavy loads but are excellent for AGVs that need to change direction or get to their destination quickly. Of course, they do not have the same load-bearing capacity as shock-absorbing AGV casters and suspension AGV casters, but they make up for it with their speed and smoothness.

Shock absorbing AGV castes can also be utilized when stability is important in an AGV. For example, many AGVs have to travel on bumpy or damaged roads and areas where a regular caster will wear out easily and need to be replaced, or might even topple the AGV over and cause mishaps. Shock-absorbing AGV casters. Though on the slower side, it can traverse all sorts of terrain without letting any damage come to the equipment or to the AGV itself. Most shock-absorbing casters use specialized rubbers and even pneumatics, which allow them to absorb even the smallest bumps that can be felt by the vehicle, allowing for smooth movement.

Of course, this will not be of much use to the operator since they will be controlling the AGV from a remote location. However, the operator will notice the longevity of the caster wheels and the smooth movement of the vehicle, which will prevent any harm from coming to the equipment that the wheels are carrying.

Benefits Of Using The Right Casters For AGVs

Shock absorbing AGV casters and suspension AGV casters are undoubtedly amongst the best casters that can be used in an AGV. So what exactly is it that makes the use of these casters so beneficial to facilities?

First of all, choosing the correct caster for your AGV will help to protect your equipment and the vehicle. This is especially true for any AGV that has to move on damaged flooring or any kind of rough terrain. The bumps and shocks from the uneven floor will make the equipment susceptible to damage.

On the other hand, using the right kind of shock-absorbing AGV casters will also increase the lifespan of the casters. Using regular casters or the incorrect casters will be unsuitable since they will wear out much more quickly and will need constant maintenance and quick replacement.

Many AGVs are also loaded automatically. There is no human intervention involved, which will help to ensure that the load has been dropped at the right pressure. So naturally, when you drop a heavy load on an AGV with an incorrect caster, there is a high chance that the caster will be impacted and will not be able to handle the initial impact. However, with the help of the right shock-absorbing caster, the AGV will be able to withstand the pressure from the initial impact and therefore prevent any damage.

Remember that you can also discuss the specifics of your facility with the caster manufacturer to ensure that you get the best deal possible. The manufacturer can help to recommend the best caster that can be utilized for your AGV and maybe even make a customized one with specialized materials that will be useful for you.

Conclusion

AGVs have specialized casters because they are crucial to most facilities and need to have the correct kind of casters to do the job properly. AGV casters are usually either shock-absorbing casters or suspension AGV casters, depending on the type of load they have to carry and the pressure from the drop-impact they might have to deal with. This is why it is crucial to have the right kinds of AGV casters.

English

English Spanish

Spanish German

German Russian

Russian Arabic

Arabic Portuguese

Portuguese Italian

Italian French

French Hebrew

Hebrew Turkish

Turkish